Products

Induction casting machine

Inf-2010

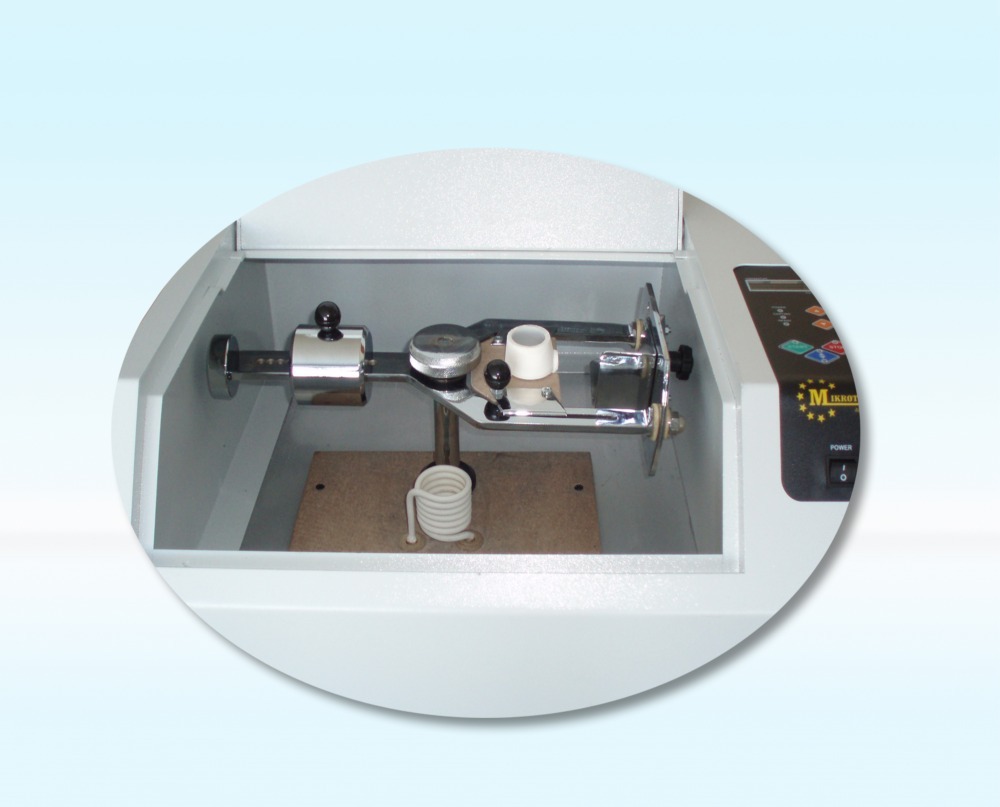

INF-2010 is the casting machine to melt and to cast the dental metal to manufacture dental metal suport. INF-2010 is operated with induction principals and melting period of 80 gr metal is just a couple of minutes, usually is less than one minute.

Heating process is implemented by isometrically that means from all of the point of the metal. It enables obtaining homogeneous heating and melting.

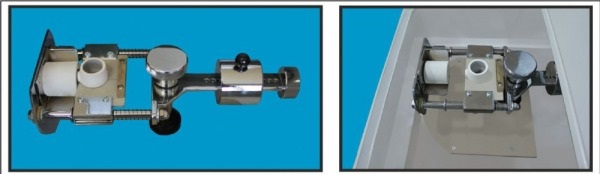

Inductional melting process is supported by centrifuge system and casted metal is manufactured in a very short time, in a couple of minutes as mentioned above. Balancing of revolution centrifuge is easy process and constant revolving speed is set properly.

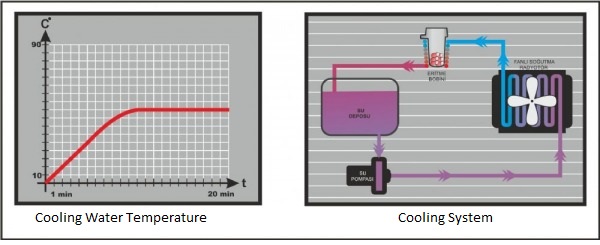

INF 2010 induction casting machine has closed circuit radiator cooling system. Cooling water circuit makes the process easy because it enables to reach high temperatures up to 1600 oC in case of requirement. This is an important advantage for continious casting and continious working period for busy schedule. In brief, Mikrotekdental INF-2010 is heavy duty machine for busy working schedule.

Another advantage is easy menu. Technician or operator is directed very clearly and using the machine is very simple. It is easy to understand the directions at the machine panel.

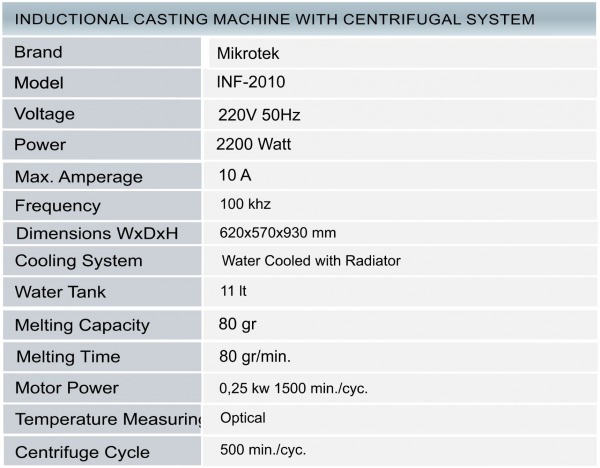

Technical Specifications